Add to Cart

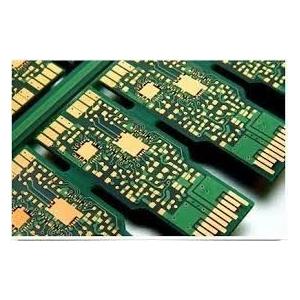

UL ENIG Heavy copper pcb Hard Drive PCB Boards turnkey service

Quick Leadtime

Lead time for sample

2-3 days for single-sided board

4-5 days for double-sided board

6-7 days for multilayer board

24-48 hours for urgent

Lead time or opening Mould:

3-5 days for normal mould

5-7 days for hard mould

Lead time for mass production

5-7 days for single/double sided board

7-10 days for multilayer board

What we need

1. Gerber files of the bare PCB

2. Bill of materials to include: Manufacturer's part number, type of part, type of packaging, component locations listed by reference designators and quantity

3. Dimensional specifications for non-standard components

4. Assembly drawing, including any change notices

5. Final test procedures (if available)

PCB Feature

| Number of Layer | 1 - 20 Layer |

| Maximum Processing Area | 680 × 1000MM |

| Min Board Thickness | 2 Layer - 0.3MM ( 12 mil ) |

| 4 Layer - 0.4MM ( 16 mil ) | |

| 6 Layer - 0.8MM ( 32 mil ) | |

| 8 Layer - 1.0MM ( 40 mil) | |

| 10 Layer - 1.1MM ( 44 mil ) | |

| 12 Layer - 1.3MM ( 52 mil ) | |

| 14 Layer - 1.5MM ( 59 mil ) | |

| 16 Layer - 1.6MM ( 63 mil ) | |

| 18 Layer - 1.8MM ( 71 mil ) | |

| Finished Board Thickness Tolerance | Thickness ≤ 1.0MM, Tolerance: ± 0.1MM |

| 1.0MM ≤ Thickness ≤ 6.5MM, Tolerance ± 10% | |

| Twisting and Bending | ≤ 0.75%, Min: 0.5% |

| Range of TG | 130 - 215 ℃ |

| Impedance Tolerance | ± 10%, Min: ± 5% |

| Hi-Pot Test | Max: 4000V/10MA/60S |

| Surface Treatment | HASL, With Lead, HASL Free Lead |

| Flash Gold, Immersion Gold | |

| Immersion Silver, Immersion Tin | |

| Gold Finger, OSP |

PCBA capability and services SMT (Surface mounting technology), COB, DIP.

1. Material Sourcing Service

2. SMT assembly and Through hole components insertion

3. IC pre-programming / Burning on-line

4. Function testing as requested

5. Complete Unit assembly (which including plastics, metal box, Coil, cable inside etc)

6. OEM/ODM also welcomed

Packing Terms

1. Inner packing. All the goods will be packed by vacuum

2. Outer packing. Standard carton